In the rigorous sectors of civil engineering, mining, and infrastructure development, project timelines often extend well beyond daylight hours. For site managers and architects, maintaining 24/7 productivity while strictly adhering to safety regulations is an operational necessity.

This is where the mobile light tower serves as a primary site asset. More than just a lamp on a pole, modern units are sophisticated pieces of equipment engineered for endurance and efficiency. In this guide, backed by PowerLink Energy’s expertise in power solutions, we break down exactly what a light tower is, its operating principles, and how to select the correct specification for your application.

What is a lighting tower?

A lighting tower is a self-contained, portable equipment unit that deliver high-lumen artificial illumination to outdoor areas where the electrical grid is unavailable or insufficient.

Structurally, it consists of a heavy-duty chassis, a telescopic mast capable of extending 20 to 30 feet, and a bank of high-output lamps. While technologies vary, the industrial standard for remote sites remains the lighting tower with generator.

How do tower lights work?

A light tower functions as a self-contained illumination system. By raising the light source, the unit minimizes glare and maximizes its footprint. This setup allows for scalable operation, where single units target specific zones or multiple towers are deployed in tandem to cover expansive industrial or construction sites.

Types of Light Towers

There are a variety of different light towers to choose from, and selecting the correct equipment depends heavily on your site’s power availability, environmental regulations, and specific operational needs.

1. Diesel Light Towers

This is the classic lighting tower with generator and remains the industry standard for good reason. Powered by a robust internal combustion engine, these units are the true workhorses of the sector. The onboard engine drives an alternator to provide a consistent, high-intensity source of electricity for the lighting unit. They are renowned for their durability and fuel efficiency compared to petrol alternatives.

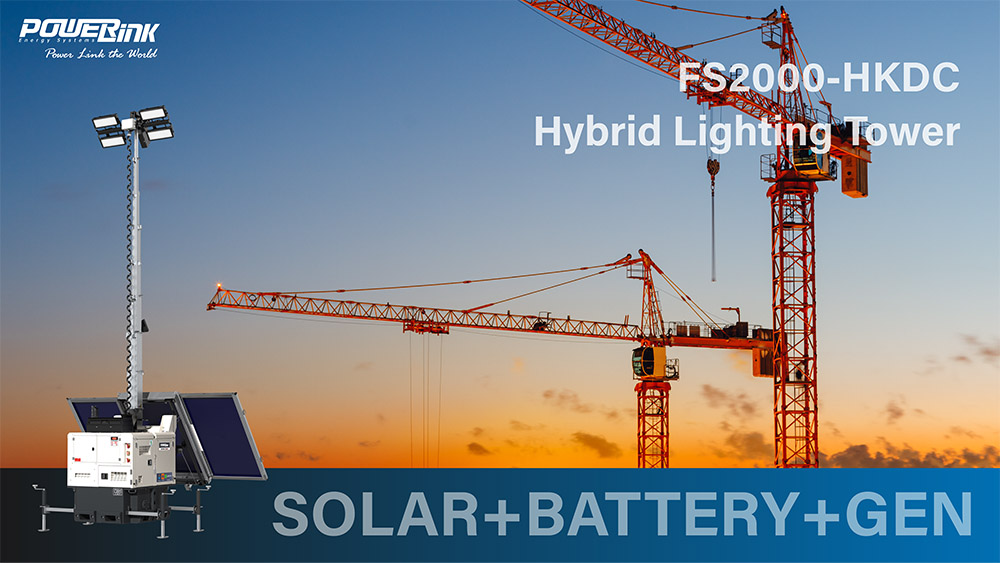

2. Solar & Hybrid Light Towers

As environmental standards tighten, these units are becoming increasingly popular, offering a sophisticated solution that balances performance with sustainability. They primarily utilize energy stored in battery banks charged by photovoltaic panels, while hybrid models feature a backup engine that automatically kicks in only when the battery level drops, ensuring continuous operation.

Beyond being environmentally friendly, they offer silent operation and can deliver substantial fuel savings. By eliminating or reducing the reliance on a running engine, they also lower the maintenance costs associated with traditional diesel units.

3. Battery-Powered Light Towers

Running strictly on stored energy, these units represent the cleanest form of portable lighting. Power comes entirely from high-capacity rechargeable batteries that can be charged via an external outlet or a built-in charging unit.

Since they produce zero noise and zero emissions at the point of use, they are the preferred option for indoor applications or noise-sensitive residential zones and events. When considering this option, one thing to note is the running time.

While many modern units can run for up to 72 hours on a single charge, this depends heavily on the battery type and light intensity settings. It is crucial to take the recharge time into account to ensure it aligns with your project schedule.

Why should engineers specify professional mobile lighting?

- Enhanced Safety: Low visibility is a leading cause of site accidents. High-lumen towers eliminate shadows and reduce trip hazards.

- Project Efficiency: They allow for extended working hours, ensuring projects meet tight deadlines regardless of seasonal daylight changes.

- Security: A well-lit site is a secure site. Light towers act as a strong deterrent against theft and vandalism during off-hours.

- Mobility: The trailer-mounted design allows the lighting to be repositioned easily as the active work zone shifts, unlike fixed streetlights.

How to Select a Light Tower

Location and Power Source

Your environment dictates the power source. Remote sites typically require the raw, continuous output of a diesel generator, whereas indoor or noise-sensitive urban zones demand the silence and zero emissions of battery-powered units. Always ensure the unit’s physical footprint fits your space constraints.

Land Size and Light Intensity

Beyond total acreage, verify the specific Lux level required for safety. For instance, precision construction often demands 20 Lux, while general excavation may only need 5 Lux. Ensure the selected unit provides sufficient brightness across the entire target area.

Mobility and Durability

For projects requiring frequent relocation, prioritize compact, portable units, but never compromise on toughness. Look for IP-rated enclosures (e.g., IP65) and galvanized chassis to ensure the equipment withstands harsh weather and rough terrain.

Budget and Efficiency

Look beyond upfront costs to long-term operational expenses. Units with LED technology and large fuel tanks can reduce fuel consumption, maintenance, and the labor downtime associated with frequent refueling.