HIGH-PRESSURE / DISCHARGE PRESSURE:13BAR

DIESEL AIR COMPRESSOR

The unit features large, wide-opening service doors that provide easy access to critical components, enabling fast and comprehensive maintenance. A user-friendly manual control panel with multiple indicator lights allows for real-time monitoring of key operating parameters.

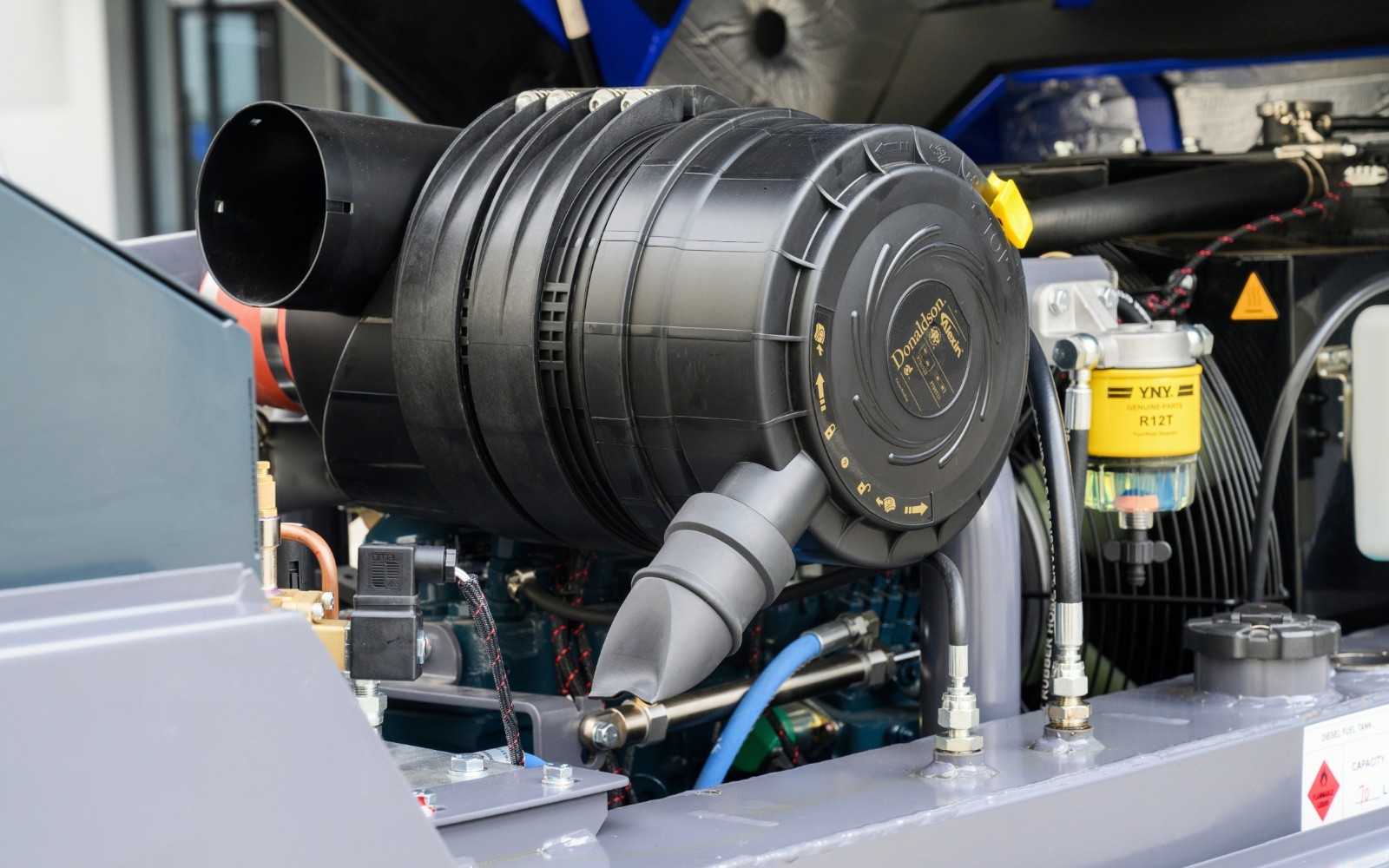

Mounted on a galvanized towing frame with service brake, the compressor offers excellent mobility and can be safely towed at highway speeds. An optional dual-stage air filter and integrated silencer provide enhanced protection for both the engine and compressor, improving reliability in harsh or dusty environments.

Ideal for extended, unattended operation, this robust and versatile mobile air compressor is perfectly suited for a wide range of applications, including manufacturing plants, construction sites, emergency repairs, mining operations, and remote job sites—delivering a reliable, turnkey solution for demanding on-the-go compressed air needs.

Rental

Mining

Factory

Outdoor Constructions

Port

Features

Environmental Adaptability

Ambient temperature: -25°C ~ 50°C. SECC canopy: IP54.

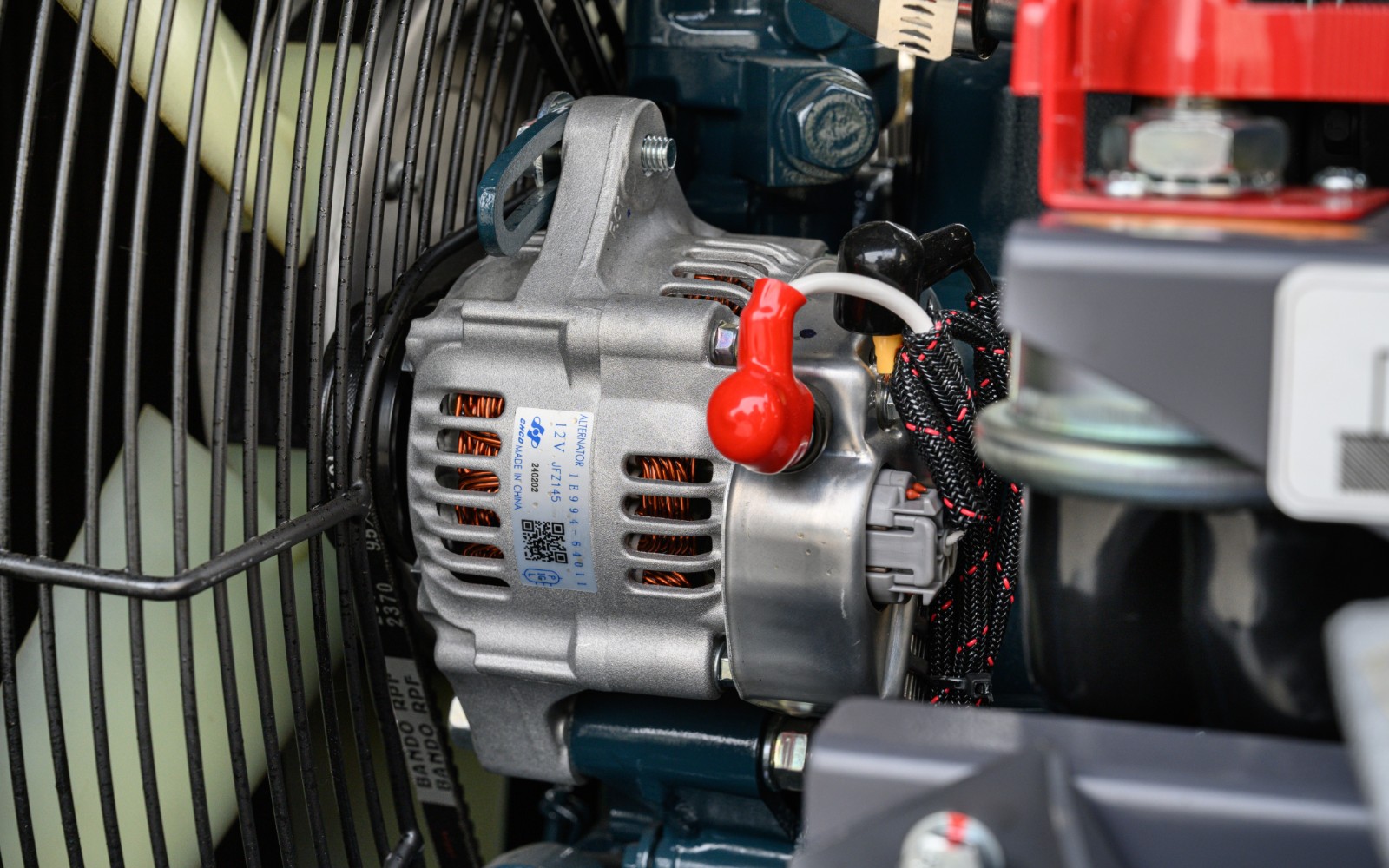

Core Power & Air System

Efficient Diesel engine. Oil-injected double-screw rotor compressor.

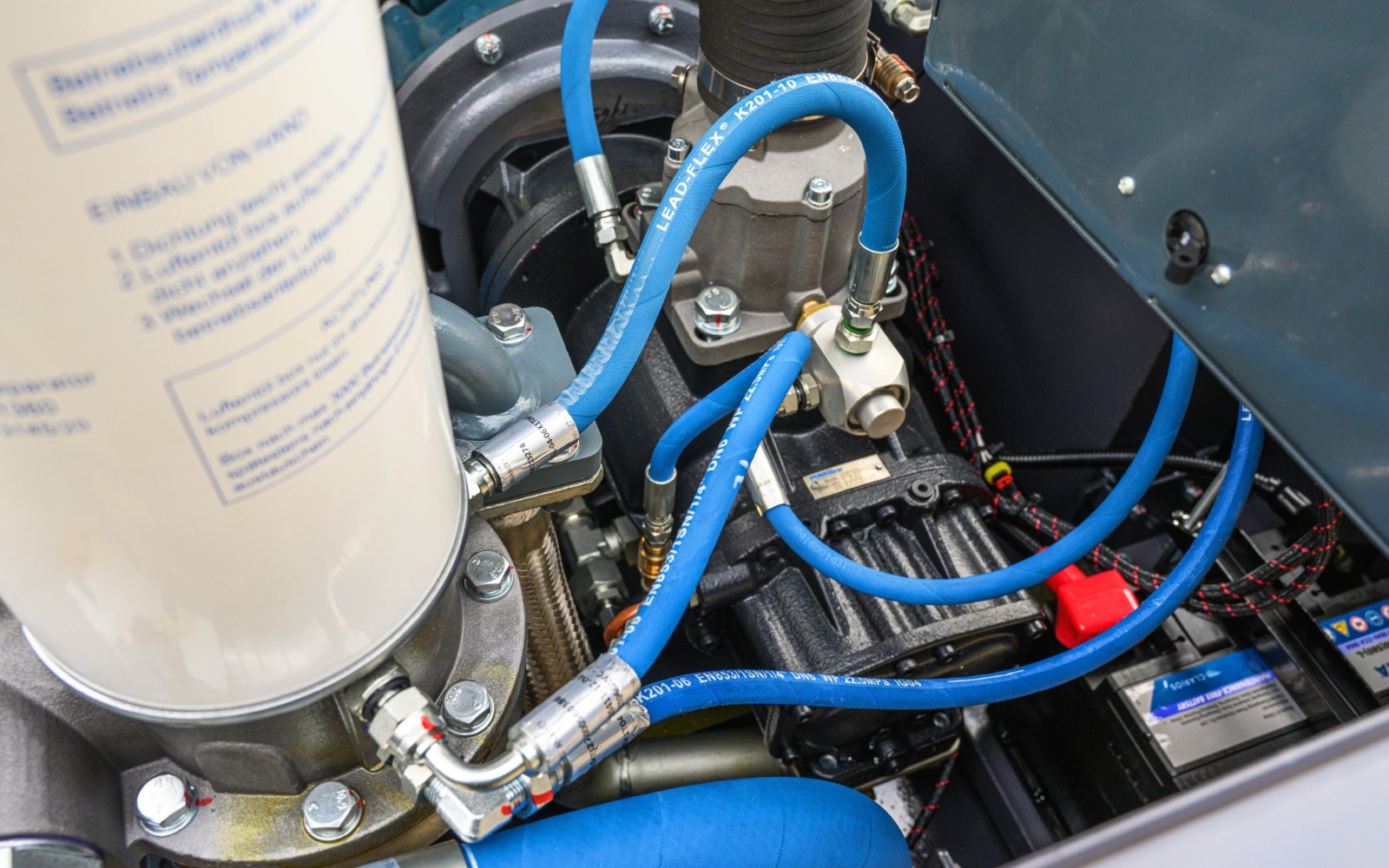

Control & Filtration

PLC intelligent controller. Dual protection air filter. industrial grade Muffler. 0-100% discharge adjustment.

Mobility & Fuel

Four-wheel drive, foldable structure.Continuous operation > 8h

Ask an Expert

PowerLink provides tailored, high-efficiency energy solutions for sustainable power around the world.

Specification

FAQs

What is the fundamental design difference between the Diesel Air Compressor A-Series and B-Series?

The primary distinction is the enclosure architecture. The A-Series focuses on accessibility via Clamshell and Gull-wing designs, while the B-Series prioritizes structural integrity through Single-boom and Double-boom configurations.

What are the operational advantages of the A-Series "Gull-wing" structure?

The Gull-wing design allows the side panels to open upward, providing a 360-degree unobstructed access point to the engine and air end, significantly reducing downtime during routine maintenance.

Under what conditions should prioritize the B-Series Double-boom design?

The Double-boom structure is essential for heavy-duty projects requiring frequent crane hoisting or deployment in rugged mining and oil and gas environments where structural rigidity is paramount.

How does the Diesel Air Compressor High-pressure Series ensure corrosion resistance in offshore or coastal environments?

The Diesel Air Compressor High-pressure utilizes high-grade galvanized steel for its enclosure and boasts an IP54 protection rating, protecting internal components against salt spray, dust, and moisture ingress.

What is the Free Air Delivery range of the Diesel Air Compressor Low-pressure Series?

The Diesel Air Compressor Low-pressure Series is designed for compact efficiency, offering a displacement range of 123 to 1243 cfm at working pressures between 7and 8 bar.

Which series is best suited for high-pressure, high-volume industrial tasks?

The Diesel Air Compressor Ultra-high pressure are the heavyweights, delivering up to 1600 cfm with discharge pressures reaching 25 bar, ideal for deep-well drilling and large-scale sandblasting.

Does the Diesel Air Compressor Low-pressure Series support stationary indoor installation?

Yes, the Diesel Air Compressor Low-pressure Series is specifically engineered as a stationary small-box structure, making it ideal for fixed factory installations or integrated skid-mounted power modules.

What type of compression technology is used across these series?

All Diesel Air Compressor utilize high-efficiency oil-injected twin-screw rotary air ends, ensuring continuous pulse-free air delivery.

How does the intake system in the Diesel Air Compressor optimize performance?

These units employ a butterfly valve intake mechanism that automatically modulates the air intake to match the system’s demand, preventing energy waste.

Are Diesel Air Compressor equipped with high-efficiency prime movers?

Yes, all series are powered by heavy-duty diesel engines that provide high torque and reliable cold-start capabilities.

What are the capabilities of the PLC Control System found in the Diesel Air Compressor?

The PLC system provides intelligent automation, including real-time telemetry, digital pressure monitoring, maintenance alerts, and automated safety shutdowns.

Can the air output be adjusted based on real-time tool usage?

Absolutely. All series feature a pneumatic control system that allows for 0-100% stepless capacity regulation, synchronizing engine speed with air demand to save fuel

What safety protections are integrated into the control logic?

The systems include protections for high discharge temperature, low engine oil pressure, high coolant temperature, and overspeed shutdown to prevent catastrophic equipment failure.

What is the maximum ambient temperature these units can operate in?

The units are standardized for High-Ambient conditions, equipped with a 50°C radiator that ensures stable operation even in extreme desert heat.

How does Diesel Air Compressor address safety around hot components?

The cooling systems include high-temperature protective guarding around radiators and exhaust manifolds to protect operators from accidental burns.

Are these compressors suitable for sub-zero climates?

Yes, All series are rated for stable operation in temperatures as low as -25°C, thanks to specialized cold-start kits and robust thermal management.

How does the Diesel Air Compressor Medium-pressure Series manage noise pollution on urban jobsites?

The Diesel Air Compressor Medium-pressure Series is integrated with industrial-grade silencers and sound-dampening enclosure materials to meet strict municipal noise regulations.

What design feature simplifies the maintenance of the Diesel Air Compressor High-pressure Series?

Despite its size, the Diesel Air Compressor High-pressure Series features oversized service doors and a spacious internal layout, allowing technicians to enter the enclosure for full-scale inspections.

How long can a Diesel Air Compressor High-pressure Series compressor run without refueling?

Equipped with a dual-layer chassis fuel tank, the Diesel Air Compressor High-pressure Series can operate continuously for more than 8 hours at full load, supporting entire work shifts without interruption.