10-2500kVA

ESV Series

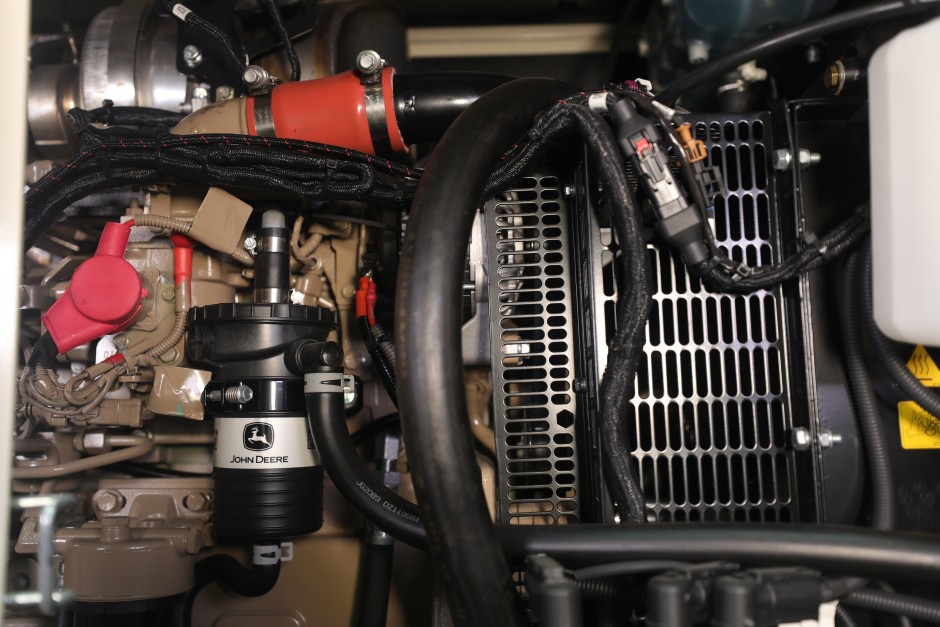

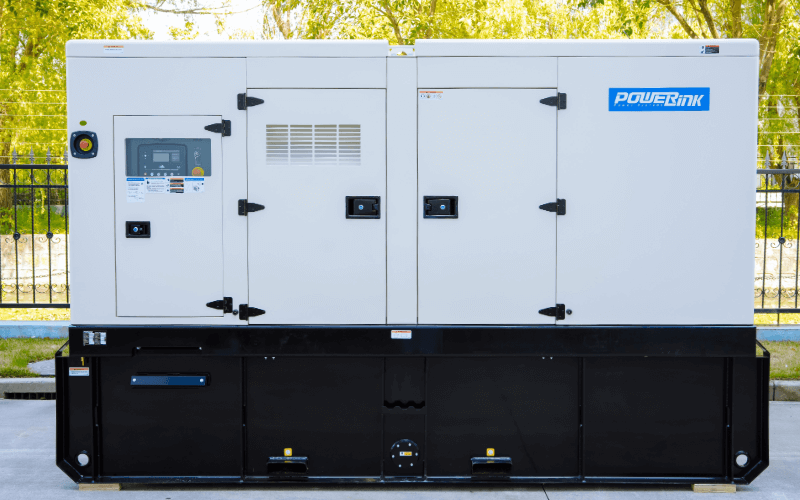

The ESV series diesel genset, an environmental diesel generator, complies with EU STAGE V EMISSION STANDARD. It offers 10-2500kVA power, tailored for the eco-conscious European market.As a green product, it surpasses emission reduction expectations. We ensure fast delivery and round-the-clock service, providing uninterrupted power and peace of mind.

Emission Standards Compliant

Meeting EU Stage V emission standards

Effortless Mobility

Easy to move, transport, and install

User-Friendly

Easy to operate, Plug and Play

Reliable Performance

Strong power output in harsh conditions

Features

Low-carbon emissions

Easy operation

Durable, safe and reliable

Strong load surge

Ask an Expert

PowerLink provides tailored, high-efficiency energy solutions for sustainable power around the world.

ESV Series

FAQs

What is the biggest feature of PowerLink?

PowerLink is a professional manufacturer of power energy equipment with over 20 years of experience in research and development, manufacturing, global sales, and service. We attach great importance to R&D investment and efficiency management.

In the field of diesel power generation, we have accumulated years of application experience in various industries and service management experience. We believe that we are an advanced and visionary enterprise in this field, and we hope to create maximum value and profit for our customers and various investment institutions.

What are the characteristics of PowerLink diesel gensets?

Modular design, advanced technology, cost-effective. As a manufacturer, we have a very deep understanding of the equipment system, both the engine, generator and other hardware, as well as the automation control and other software, are developed and mastered by PowerLink.

What types of applications does PowerLink provide gensets for?

PowerLink provides customers with all types of continuous energy. We produce diesel units as small as 5KVA, ideal for homes and small retail properties, up to 3250KVA, which can provide electricity for commercial buildings, hotels, hospitals, mines and factories, and even feed back into the national power supply network.

Main application types:

1) Standby power supply, telecommunications, data centers and other places need diesel gensets to provide backup power, as a large grid supplementary energy for emergency backup.

2) Continuous power supply; Far away from the urban more remote places, the lack of electricity, the need for diesel generators to provide continuous power.

Applications: commercial, industrial, urban buildings, hotels, guesthouses, airports, hospitals, schools, residential communities, bathing centers, entertainment clubs, data centers, mines, docks…

Our generator can be manually or automatically started, with structural types including open, silent box, container, and trailer mounted generator sets.

The type of generator you need will vary depending on your power supply method, installation location, and whether it needs to operate continuously or only during power outages. To determine which type of generator is most suitable for you, please contact your local PowerLink dealer, who will be able to provide the appropriate product according to your requirements.

How to calculate and analyse return on investment?

First, you need to determine the local energy structure, understand the cost of key elements such as electricity, gas, and fuel, as well as monthly energy cost expenditures. Please send this information to us, and our sales experts will provide you with a detailed investment return analysis.

How to choose your new power generation equipment?

Many customers need to consider the technical and economic feasibility of diesel power generation solutions. Usually the diesel genset is combined with the external large power grid, and the energy supply complements each other, which can improve the reliability and flexibility of the entire system.

To find a cost-effective, technically reliable and more environmentally friendly power generation solution, we recommend that you consider the following important factors when choosing a power generation equipment:

- The most important thing is the installation cost. Diesel genset solutions offer very competitive installation costs compared to other power generation systems, with a limited footprint for a single kilowatt project.

- Power generation efficiency. The power generation efficiency of diesel gensets directly affects the economy of the project. PowerLink diesel gensets are efficient and offer a high value.

- Manufacturing and commissioning time. PowerLink diesel gensets usually take 3 to 6 months from production time plus construction and commissioning time. Your cash on delivery time will be shorter if you have it in stock.

- Modular installation solution. Considering that the equipment is ultimately delivered safely to the installation site, the modular structure makes project installation easier and commissioning simpler and faster.

- Another very important factor in determining the choice of power generation equipment: the operating expenses associated with the equipment. These aspects need to be considered: service intervals, spare parts costs, downtime during maintenance, and the entire working cycle of the equipment before the overhaul. Based on our long experience, we offer multi-year service contracts for PowerLink gensets. This can help reduce the need for spare parts and can predict service times in advance, reducing operating costs throughout the engine’s working life.

- Help you select the most suitable equipment through the load analysis of the project. PowerLink’s wide range of diesel engines (5 to 3250KVA) will help you find the right solution for you.

- The surrounding environmental conditions will have an impact on the use of the equipment, thus affecting its actual power output capacity. In other words, in some cases, your power output may be much lower than the rated power. If you plan to operate equipment at high temperatures and/or altitudes significantly above sea level, be aware of this factor.

Do you provide transfer switches and distribution equipment to allocate power?

PowerLink currently provides automatic transfer switches and power transmission and distribution systems, which can be customized according to the actual situation of the project.

How is the genset noise reduced?

The following three methods are usually used for noise reduction:

- Exhaust noise reduction: exhaust noise is the main source of generator noise, and a special muffler is usually selected for noise reduction.

- Reducing axial fan noise.

- Sound insulation and noise reduction treatment of the machine room and genset vibration isolation.

How long is the product delivery cycle?

For standard products, from the time the customer places the order until the product is shipped, depending on the power and series, it generally takes 2-6 months.

What do you need to know when installing a genset?

When installing a genset, the following aspects should be noted:

- The installation site should have good ventilation, with sufficient air intake at the generator end and good exhaust at the engine end.

- The surroundings of the installation site should be kept clean, and items that can produce corrosive gases and vapours such as acidic and alkaline substances should be avoided nearby. Fire-fighting equipment should be available where possible.

- If used indoors, the exhaust pipe must be vented outdoors, and the pipe diameter must be greater than or equal to the exhaust pipe diameter of the muffler. The number of elbows in the connected pipe should not exceed three, to ensure smooth exhaust. The pipe should be inclined downward at 5-10 degrees to prevent rainwater from entering. If the exhaust pipe is vertically installed, a rain cover must be added.

- When using a concrete foundation, use a spirit level to ensure its levelness during installation, so that the unit is fixed on a level foundation. Special shock-absorbing pads or base bolts should be used between the unit and the foundation.

- The genset’s outer shell must have a reliable protective ground. For generators that require a neutral point directly grounded, a professional should perform the neutral point grounding and be equipped with lightning protection devices. It is strictly forbidden to use the grounding device of the power grid to directly ground the neutral point.

- The bidirectional switch between the generator and the power grid must be very reliable to prevent reverse power transmission, this switch must also be tested and approved by the local power department.

- The wiring for starting the battery must be secure.

How to protect the AC generator of the genset?

Three different methods can be used to protect the AC generator of the genset:

- Thermal-magnetic protection (TMP) – TMP protects the AC generator from overload and short circuit effects. If overloaded, TMP will shut off after a specified period which depends on the type of overload. The higher the overload, the shorter the time needed for TMP to shut off, while in the case of a short circuit, TMP will always shut off immediately.

- Leakage protection – When a leakage fault between phases and ground exceeds 30mA, 100mA, or 300mA, ELP will automatically interrupt the circuit, depending on the type of leakage switch used. In the case of indirect contact, ELP can protect personnel from electric shock and additionally, ELP can also be used as a short-circuit protection. In most cases, an earthing pin is required!

- Insulation protection – An insulation protection relay is used to measure and protect the insulation (actually resistance) between a direct, ungrounded AC power source and a freely selectable grounded area (i.e. the frame or mass of a genset). In this way, users can be protected from electric shock when accessing the normal user-friendly area of the machine. When insulation failure occurs, the tension of the AC generator can be interrupted, the engine can stop, or an alarm can be activated. In this case, no grounding pin is required!