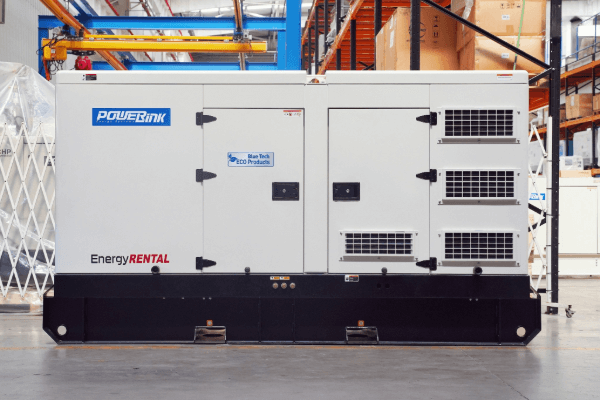

30-1500kVA

EC Series

The EC Series diesel generator sets offer a versatile power range from 30 kVA to 1500 kVA, featuring premium Cummins engines and Stamford alternators. These Cummins engine generators are engineered to provide exceptional reliability and durability. They serve effectively as both a continuous power source and a robust solution for emergency or backup power.

With their cost-effective design, the EC Series generators offer excellent performance and efficiency for various applications.

Quick Star

Fast startup with strong load surge

capability

Portable

Easy to transport and install.

User-Friendly

Plug-and-play operation.

Reliable

Performs well in harsh conditions.

Features

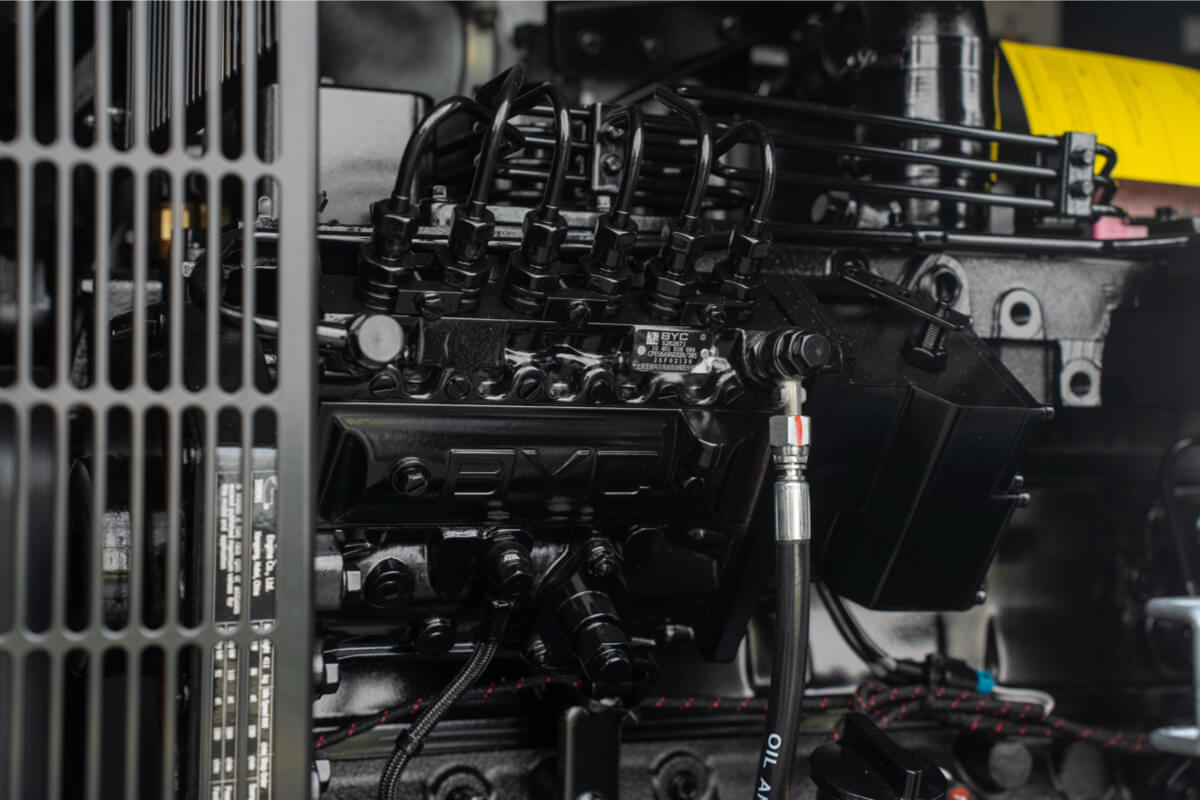

Reliable & Durable

Delivers stable power in harsh conditions

Quick startup with strong load surge capacity

Strong load surge capacity

User-friendly

Simple plug-and-play operation

Ask an Expert

PowerLink provides tailored, high-efficiency energy solutions for sustainable power around the world.

EC Series Specification

Case & Solution

500KVA Emergency Power Project

- Location: Nepal

- Equipment: 1*GMS500CS Diesel Generator

- Electric output mode: Emergency Power

- Field / fuel: Stadium Centre / Diesel

- Total output power: 500KVA

Australian Remote Copper Mine

- Location: Central QLD, Australia

- Equipment: 3*GMS1375CS-AU & 1*WCS550CS-AU

- Electric output mode: Prime Supply

- Field / fuel: Mining / Diesel

- Total output power: 4MVA

Africa Water Station Power Project

- Location: Baborone, Africa

- Equipment: 1*GMS500CS+1*GMS250CS

- Electric output mode: Prime Power

- Field / fuel: Power Station / Diesel

- Total output power: 750KVA

FAQs

How to choose your new power generation equipment?

Many customers need to consider the technical and economic feasibility of diesel power generation solutions. Usually the diesel genset is combined with the external large power grid, and the energy supply complements each other, which can improve the reliability and flexibility of the entire system.

To find a cost-effective, technically reliable and more environmentally friendly power generation solution, we recommend that you consider the following important factors when choosing a power generation equipment:

- The most important thing is the installation cost. Diesel genset solutions offer very competitive installation costs compared to other power generation systems, with a limited footprint for a single kilowatt project.

- Power generation efficiency. The power generation efficiency of diesel gensets directly affects the economy of the project. PowerLink diesel gensets are efficient and offer a high value.

- Manufacturing and commissioning time. PowerLink diesel gensets usually take 3 to 6 months from production time plus construction and commissioning time. Your cash on delivery time will be shorter if you have it in stock.

- Modular installation solution. Considering that the equipment is ultimately delivered safely to the installation site, the modular structure makes project installation easier and commissioning simpler and faster.

- Another very important factor in determining the choice of power generation equipment: the operating expenses associated with the equipment. These aspects need to be considered: service intervals, spare parts costs, downtime during maintenance, and the entire working cycle of the equipment before the overhaul. Based on our long experience, we offer multi-year service contracts for PowerLink gensets. This can help reduce the need for spare parts and can predict service times in advance, reducing operating costs throughout the engine’s working life.

- Help you select the most suitable equipment through the load analysis of the project. PowerLink’s wide range of diesel engines (5 to 3250KVA) will help you find the right solution for you.

- The surrounding environmental conditions will have an impact on the use of the equipment, thus affecting its actual power output capacity. In other words, in some cases, your power output may be much lower than the rated power. If you plan to operate equipment at high temperatures and/or altitudes significantly above sea level, be aware of this factor.

How is the genset noise reduced?

The following three methods are usually used for noise reduction:

- Exhaust noise reduction: exhaust noise is the main source of generator noise, and a special muffler is usually selected for noise reduction.

- Reducing axial fan noise.

- Sound insulation and noise reduction treatment of the machine room and genset vibration isolation.

What is the backpower? What are the two serious consequences?

The case of self-provided generator sending power to the municipal network is called reverse power supply. There are two kinds of serious consequences:

- The municipal power grid is not cut off, and the city network power supply and the self-provided generator power supply produce non-synchronous operation, which will destroy the unit. If the capacity of the self-provided generator is large, it will also cause the municipal power grid to shake.

- The city network has been outage is being tested, and its self-provided generator provides power backwards. It will electrocute some of the inspection staff.

What are the reasons why the water temperature is high and the alarm stops and cannot be used?

- Water tank leakage or insufficient water;

- The water temperature sensor is damaged.

- The water tank waterway dirt is too thick, or the heat sink oil is too much.

- Fan belt wear is too large, and there is insufficient pressure.

- Pump wear, pump water is insufficient.

- The thermostat opening Angle is not enough; there is a stuck phenomenon.

- The cylinder gasket is damaged, and the water channel is connected to the cylinder.

- The cylinder liner wears too much, and there is local water seepage.

- The ventilation of the equipment room does not meet the requirements.

- Engine overload operation;

- Excessive fuel supply (including engine weakness).

How is the genset used in coordination with the main power supply?

Stable commercial power is supplied to the power load through cables. When the main power supply is interrupted due to a power outage, a signal is sent from the transfer switch to the genset, and then the genset starts and sends the generated power to the load. When the main power supply is restored, the switch will cut off the power supply of the genset and restore it to the main power supply.